Introduction

When the summer sun bears down and the heat becomes unbearable, there’s nothing worse than a faulty air conditioner. If your AC unit isn’t cooling as effectively as it used to, the culprit might be a malfunctioning compressor. Replacing an AC compressor can seem like a daunting task, but with the right tools and a bit of patience, it’s entirely doable as a DIY project.

Source hvacseer.com

What is an AC Compressor?

The compressor is the heart of your AC system. It’s responsible for compressing refrigerant gas, which then absorbs heat from the air inside your home. The compressed gas is then pumped outside, where it releases the heat and cools down before being circulated back into your home.

Signs of a Faulty Compressor

How do you know if your AC compressor is on its last legs? Here are some telltale signs:

- Reduced cooling performance: Your AC unit is struggling to keep your home cool, even on low settings.

- Strange noises: You hear unusual sounds coming from the outdoor unit, such as grinding, rattling, or humming.

- High energy bills: The compressor is consuming more energy than usual to try and compensate for its reduced performance.

- Short cycling: The AC unit turns on and off frequently, preventing it from reaching its full cooling potential.

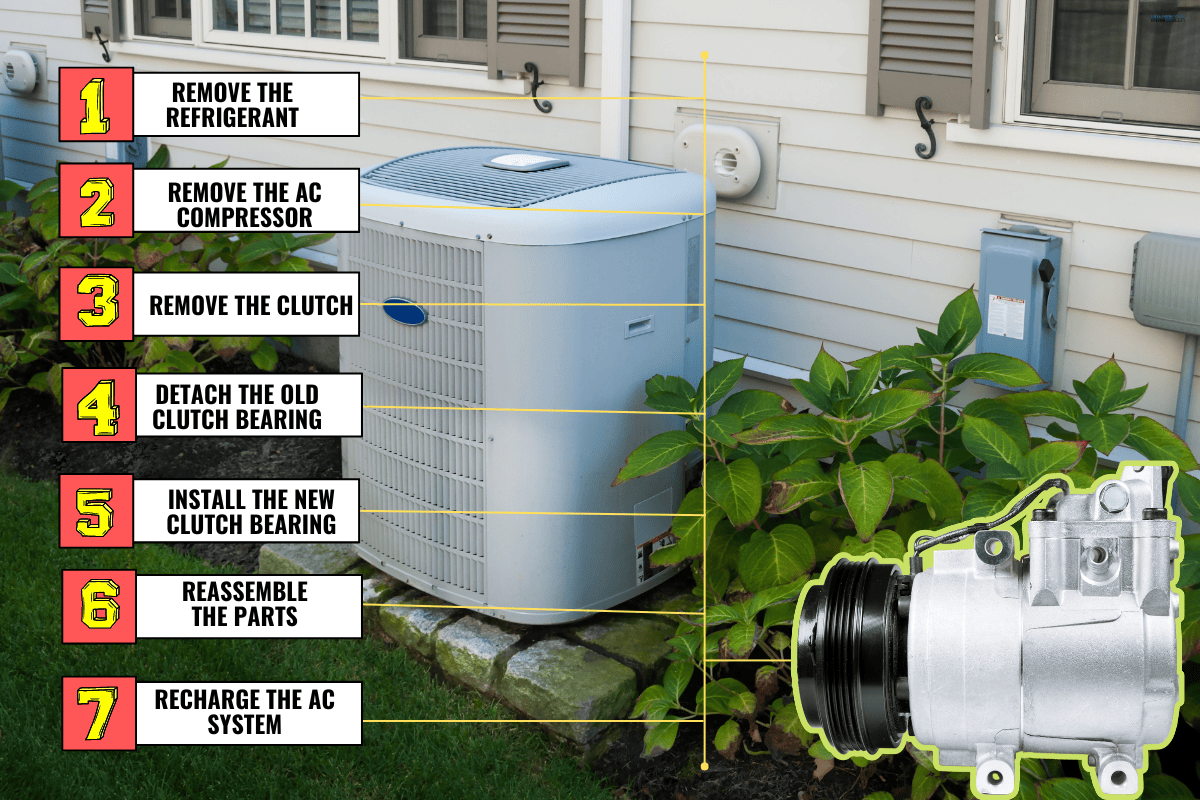

How to Change an AC Compressor: A Step-by-Step Guide

Materials you’ll need:

- New AC compressor compatible with your unit

- Refrigerant (R-22 or R-410A)

- Refrigerant hoses

- Vacuum pump

- Manifold gauge set

- Screwdriver

- Wrench

- Safety glasses

- Gloves

Step 1: Safety First

Before you start, turn off the power to your AC unit at the breaker and disconnect the electrical wires. Wear safety glasses and gloves to protect yourself from refrigerant and metal shavings.

Step 2: Remove the Old Compressor

Locate the compressor in the outdoor unit. It’s usually a large cylindrical or rectangular component with copper lines connected to it. Disconnect the electrical wires and refrigerant lines using a wrench or screwdriver. Carefully remove the old compressor from its mounting bracket.

Step 3: Prepare the New Compressor

Unpack the new compressor and remove any protective caps or plugs. Connect the refrigerant lines to the corresponding ports on the compressor, tightening the nuts securely. Attach the electrical wires to the appropriate terminals.

Step 4: Install the New Compressor

Mount the new compressor onto the bracket in the outdoor unit. Make sure it’s securely fastened. Connect the electrical wires and refrigerant lines to the unit’s corresponding connections. Tighten all fittings using a wrench.

Step 5: Evacuate the System

Connect the vacuum pump to the AC unit’s service ports. Turn on the pump and evacuate the system for at least 30 minutes to remove all air and moisture.

Step 6: Charge the Refrigerant

Attach the refrigerant hoses to the service ports and connect them to the refrigerant tank. Open the valve on the tank and slowly add refrigerant to the system until the pressure reaches the manufacturer’s recommended level.

Step 7: Test the System

Turn on the AC unit and check if it’s cooling effectively. Monitor the pressure on the manifold gauge set to ensure it’s within the acceptable range. If everything is working correctly, close the refrigerant tank valve and remove the hoses.

Troubleshooting Tips

- Won’t turn on: Check the power supply and ensure the compressor is properly connected electrically.

- Overheating: Inspect the condenser coils for dirt or debris and clean if necessary. Check the refrigerant levels and add more if needed.

- Refrigerant leak: Use a leak detector to identify the source of the leak and repair or replace the faulty component.

Comparison Table: Replacing an AC Compressor vs. Hiring a Professional

| Factor | DIY | Hiring a Professional |

|---|---|---|

| Cost | Lower (parts and tools required) | Higher (labor and expertise) |

| Time | Takes several hours | Usually completed within a day |

| Skill level | Requires basic mechanical skills | Requires specialized knowledge and experience |

| Warranty | Limited to parts and labor | Usually includes a comprehensive warranty |

| Potential risks | Refrigerant exposure, electrical hazards | Negligible if the professional is licensed and insured |

Conclusion

Replacing an AC compressor can be a challenging but rewarding DIY project. By following the steps outlined above, you can save money and keep your home cool during those scorching summer months. If you encounter any issues along the way, don’t hesitate to consult a qualified HVAC technician.

Check out our other articles for more helpful tips on home maintenance and repairs:

- How to Fix a Leaky Faucet

- DIY Guide to Replacing a Water Heater

- Maintaining Your HVAC System for Year-Round Comfort

FAQ about How to Change AC Compressor

How do I know if my AC compressor needs to be changed?

- P: Signs of a failing compressor include: no cold air, warm air, strange noises (whining, grinding), and leaks.

- A: To confirm, check if the compressor is running (vibrates slightly). If it’s not, the compressor may need replacing.

What tools do I need to change an AC compressor?

- P: Essential tools include: refrigerant recovery machine, vacuum pump, torque wrench, refrigerant gauges, hex keys, and safety glasses.

- A: Consider renting specialized tools like the refrigerant recovery machine if you don’t own them.

Can I change an AC compressor myself?

- P: It’s possible, but only if you have the necessary knowledge, tools, and safety precautions.

- A: It’s recommended to hire a qualified HVAC technician if you’re not experienced with AC repairs.

How much does it cost to change an AC compressor?

- P: The cost varies depending on factors like AC unit size, labor costs, and refrigerant type.

- A: Expect to pay around $1,500-$3,000 for a replacement, including parts and labor.

What refrigerant should I use for the new compressor?

- P: Check your old compressor for the refrigerant type (e.g., R-22, R-410A).

- A: Use the same type of refrigerant or a compatible replacement recommended by the manufacturer.

Do I need to vacuum the AC system before adding refrigerant?

- P: Yes, it’s crucial.

- A: Vacuuming removes air and moisture from the system, preventing contamination and ensuring proper operation.

How do I connect the electrical wires to the new compressor?

- P: Follow the wiring diagram provided by the manufacturer.

- A: Use a torque wrench to tighten the connections properly.

How much refrigerant should I add to the system?

- P: Refer to the manufacturer’s specifications.

- A: Overcharging can damage the system, so add refrigerant gradually until the desired pressure is reached.

How can I check for leaks?

- P: Use a leak detector or soapy water solution.

- A: Run the AC unit and apply the solution to potential leak points. Bubbles will indicate a leak.

Is it necessary to flush the AC system when changing the compressor?

- P: Yes, if the old compressor has failed due to internal damage.

- A: Flushing removes contaminants and debris that may have accumulated in the system.