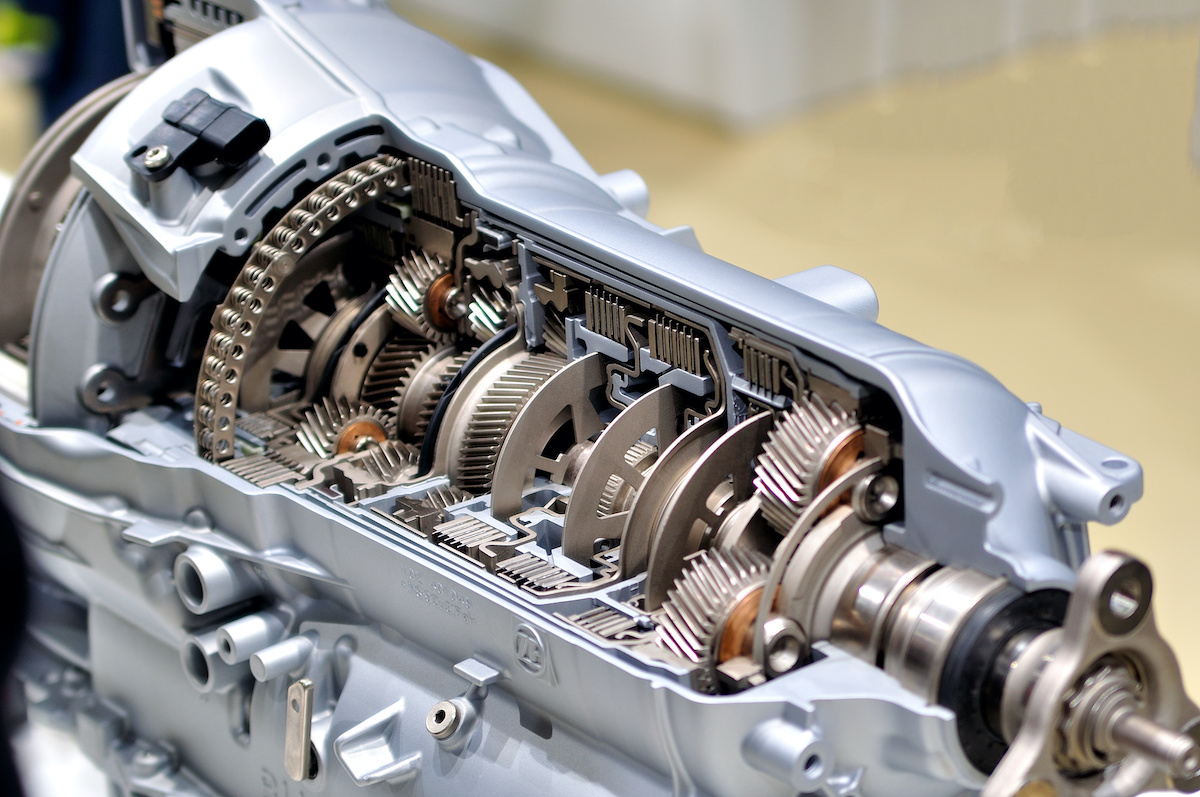

Rebuilding Your Transmission: A Step-by-Step Guide

Is your transmission giving you nightmares? Don’t worry, you’re not alone! Transmission problems can be a major headache, but they don’t have to be a financial nightmare. With the right tools and a little know-how, you can tackle this challenge yourself and save a bundle.

Source woodiesautoservice.com

Why Rebuild Your Transmission?

Rebuilding a transmission can be a daunting task, but it’s often the most cost-effective option for older vehicles or those with high mileage. Here are a few key reasons to consider rebuilding:

- Cost: Rebuilding a transmission typically costs less than half the price of a new one.

- Reliability: A properly rebuilt transmission can last as long as a new one.

- Control: You’ll have complete control over the rebuilding process and can ensure that your transmission is built to your exact specifications.

Tools and Equipment You’ll Need

Before you tackle this project, make sure you have the right tools and equipment. Here’s a basic list:

- Transmission jack

- Floor jack and jack stands

- Socket set

- Torque wrench

- Transmission rebuild kit

- Sealant

- RTV silicone

- Parts cleaner

- Gloves

- Safety glasses

Safety First!

Before you start, always prioritize safety. Wear gloves and safety glasses, and be sure to support the transmission with a jack and jack stands.

Step-by-Step Guide to Rebuilding a Transmission

Now, let’s dive into the step-by-step guide:

1. Remove the Transmission

Disconnect the battery and drain the transmission fluid. Then, remove the drive shaft, starter, and any other components that block access to the transmission bolts. Once the bolts are removed, use a transmission jack to lower the transmission.

2. Disassemble the Transmission

Place the transmission on a stable surface and open the case. Carefully remove the gears, clutches, and other internal components. Inspect each part for wear and tear, and replace any damaged items with new ones from the rebuild kit.

3. Clean and Inspect the Transmission Case

Clean the transmission case thoroughly using a parts cleaner. Inspect the case for cracks or damage and repair any issues you find.

4. Reassemble the Transmission

Reassemble the transmission by following the reverse order of disassembly. Lubricate all moving parts with transmission fluid, and tighten all bolts to the specified torque.

5. Install the Transmission

Carefully lift the transmission into place and bolt it to the engine and transmission mount. Reconnect all removed components and refill the transmission with fresh fluid.

6. Check for Leaks

Start the engine and let it idle while you check for leaks. If you find any leaks, stop the engine and tighten the bolts or clamps until the leak stops.

7. Test Drive

After checking for leaks, take your vehicle for a test drive. Gradually increase the speed and load on the transmission to ensure it’s shifting smoothly and without any issues.

Conclusion

Rebuilding a transmission can be a challenging but rewarding project. By following these steps and taking the necessary precautions, you can save yourself thousands of dollars and ensure that your vehicle is running smoothly for years to come.

Don’t forget to check out our other articles for more DIY automotive tips and tricks!

FAQ about How to Rebuild a Transmission

1. What tools do I need to rebuild a transmission?

- P: You’ll need a transmission jack, a torque wrench, a socket set, a screwdriver set, and a variety of other specialized tools.

- A: Make sure you have the right tools for the job before you start.

2. How long does it take to rebuild a transmission?

- P: It depends on the make and model of the transmission, but it can take anywhere from a few hours to a few days.

- A: Be prepared to spend a significant amount of time on this project.

3. What is the most difficult part of rebuilding a transmission?

- P: The most difficult part is typically removing and reinstalling the transmission. It can be heavy and awkward to work with.

- A: Get help from a friend or a mechanic if you’re not comfortable doing this part yourself.

4. What are some tips for rebuilding a transmission?

- P: Some tips include:

- Take your time.

- Follow the instructions carefully.

- Use the right tools.

- Be patient.

- A: Follow these tips to increase your chances of success.

5. What should I do if I get stuck?

- P: If you get stuck, don’t be afraid to ask for help from a friend, a mechanic, or an online forum.

- A: There are many resources available to help you with this project.

6. How much does it cost to rebuild a transmission?

- P: The cost of rebuilding a transmission varies depending on the make and model of the transmission, as well as the cost of parts and labor.

- A: Be prepared to spend anywhere from a few hundred dollars to a few thousand dollars.

7. Is it worth rebuilding a transmission?

- P: Whether or not it’s worth rebuilding a transmission depends on the age and condition of the transmission, as well as the cost of replacement.

- A: Consider all of these factors before making a decision.

8. How can I tell if my transmission needs to be rebuilt?

- P: Some signs that your transmission needs to be rebuilt include:

- Slipping gears

- Grinding noises

- Leaking fluid

- A: If you’re experiencing any of these symptoms, it’s important to have your transmission checked by a mechanic.

9. Can I rebuild a transmission myself?

- P: Yes, it is possible to rebuild a transmission yourself, but it is a challenging project.

- A: If you’re not mechanically inclined, it’s best to leave this job to a professional.

10. Where can I find more information about rebuilding transmissions?

- P: There are many resources available online and in libraries that can provide you with more information about rebuilding transmissions.

- A: Do some research before you start this project.